Beyond Metal: The Rise of Composite Materials in Car Construction

betbhai9, playexch in login, lotus 365.vip: When it comes to car construction, metal has long been the material of choice. From steel to aluminum, metal has been the go-to material for building the sturdy bodies and frames of vehicles. However, in recent years, there has been a rising trend towards the use of composite materials in car construction. These materials offer a lightweight, durable, and energy-efficient alternative to traditional metals, making them an attractive option for car manufacturers looking to improve their vehicles’ performance and efficiency.

Composite materials are made up of two or more different materials that, when combined, create a new material with unique properties. These materials can include carbon fiber, fiberglass, Kevlar, and other synthetic fibers, as well as resins and polymers. When used in car construction, composite materials offer several advantages over traditional metals. These advantages include:

1. Lightweight: Composite materials are significantly lighter than traditional metals, which can help improve fuel efficiency and performance. Lighter vehicles require less energy to accelerate and can achieve better gas mileage.

2. Strength: Despite being lightweight, composite materials are incredibly strong and durable. They can withstand impacts and vibrations better than metal, leading to improved safety and longevity for vehicles constructed with composites.

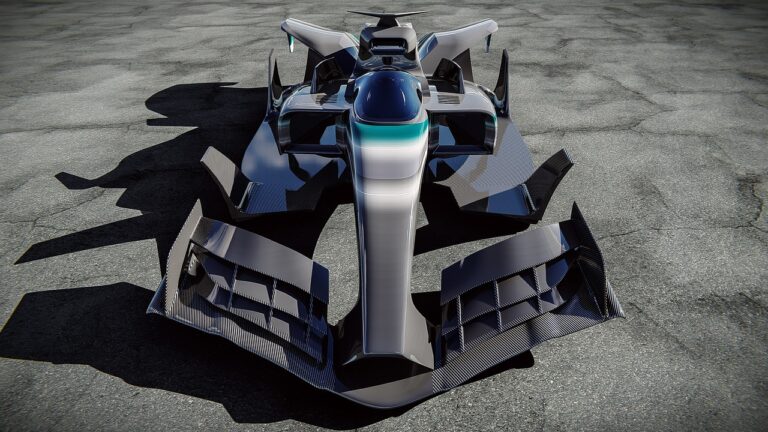

3. Design Flexibility: Composite materials can be molded into virtually any shape, allowing car manufacturers to create sleek, aerodynamic designs that are difficult to achieve with traditional metals. This design flexibility can result in vehicles with improved performance and aesthetics.

4. Corrosion Resistance: Unlike metal, composite materials are not susceptible to rust and corrosion, making them an ideal choice for vehicles that are exposed to harsh weather conditions or chemicals on the road.

5. Thermal Insulation: Composite materials have excellent thermal insulation properties, helping to keep the vehicle’s interior cool in hot weather and warm in cold weather. This can improve comfort for passengers and reduce the need for air conditioning and heating systems, leading to energy savings.

6. Recyclability: Many composite materials are recyclable, making them a more sustainable option compared to traditional metals. Car manufacturers can reduce their environmental impact by using recyclable composites in their vehicles.

With these advantages in mind, it’s no surprise that car manufacturers are increasingly turning to composite materials for car construction. The rise of electric vehicles (EVs) has further boosted the demand for lightweight materials that can help extend the range of EVs and improve their overall performance. Composite materials are well-suited for EVs due to their lightweight and energy-efficient properties, making them an excellent choice for the future of automotive technology.

As car manufacturers continue to innovate and push the boundaries of what is possible in car construction, we can expect to see more vehicles incorporating composite materials in the coming years. From electric cars to sports cars, composite materials are poised to revolutionize the automotive industry and offer consumers a new era of high-performance, energy-efficient vehicles.

In conclusion, the rise of composite materials in car construction represents a significant shift in the automotive industry towards more lightweight, durable, and energy-efficient vehicles. With their numerous advantages over traditional metals, composite materials are set to play a key role in shaping the future of automotive technology. As car manufacturers continue to explore new ways to improve their vehicles’ performance and efficiency, we can expect to see composite materials become an essential component of car construction for years to come.

—

**FAQs**

Q: Are composite materials more expensive than traditional metals?

A: While composite materials can be more expensive upfront, their lightweight properties can lead to long-term cost savings in fuel efficiency and maintenance.

Q: How do composite materials impact vehicle safety?

A: Composite materials are incredibly strong and durable, making them an excellent choice for improving vehicle safety and crashworthiness.

Q: Can composite materials be repaired if damaged?

A: Yes, composite materials can be repaired, although the process may be more complex compared to traditional metal repairs. It’s essential to consult with a professional if your composite vehicle requires repairs.

Q: Are composite materials environmentally friendly?

A: Many composite materials are recyclable, making them a more sustainable option compared to traditional metals. Car manufacturers can reduce their environmental impact by using recyclable composites in their vehicles.